Precision Angular Contact Bearings

Reliable and Efficient Performance | Custom Solutions Available

Angular Contact Ball Bearings

An angular contact ball bearing is a type of rolling bearing designed to handle both radial and axial loads. People call forces in combination loads. The key point about an angular contact bearing is the inner and outer raceways are angled in relation to the axis of the bearing so the rolling elements(typically balls) make contact at an angle.

Advantages of Angular Contact Ball Bearings

Advantages

- Simple structure.

- Higher limit speed.

- Lower friction torque.

- Can simultaneously bear both radial and axial loads.

- For the same outer dimensions, they have a higher dynamic load capacity and static load capacity than deep groove ball bearings.

- High rotational precision and low noise.

Types

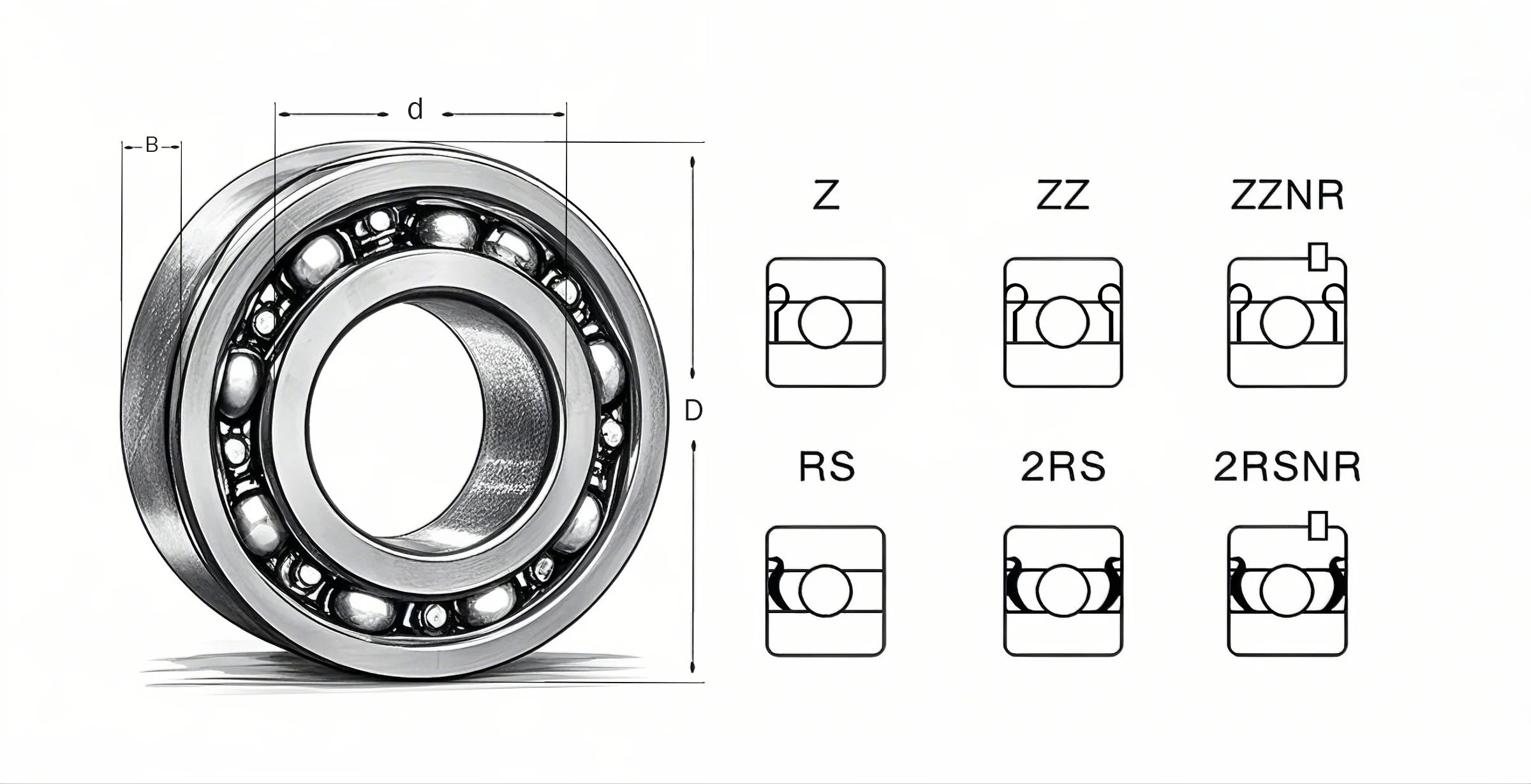

Technical specifications and parameters

For more specifications, please contact us for consultation.

To understand the meaning of bearing model letters, please click

| Model | Size | RATED LOAD | ||||

| d(mm) | D(mm) | B(mm) | r(min.) | Static C(N) | Dynamic C(N) | |

| 7305 B | 25 | 62 | 17 | 1.1 | 24 400 | 14 600 |

| 7906 A5 | 30 | 47 | 9 | 0.3 | 7 850 | 5 950 |

| 7907 A5 | 35 | 55 | 10 | 0.6 | 11 400 | 8 700 |

| 7008 A | 40 | 68 | 15 | 1 | 19 500 | 15 400 |

| 7000 C | 10 | 26 | 8 | 0.3 | 5 300 | 2 490 |

| 7201 A | 12 | 32 | 10 | 0.6 | 8 000 | 4 050 |

| 7214 A | 70 | 125 | 24 | 1.5 | 76 500 | 63 500 |

| 7016 C | 80 | 125 | 22 | 1.1 | 58 500 | 55 500 |

| 7234 A | 170 | 310 | 52 | 4 | 295 500 | 36 600 |

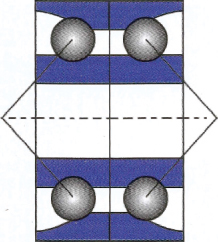

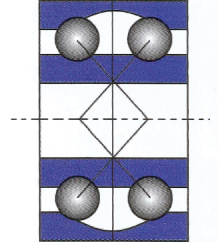

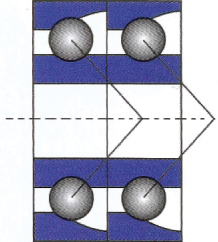

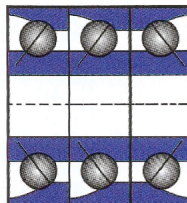

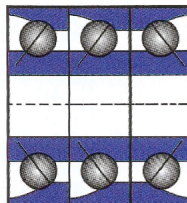

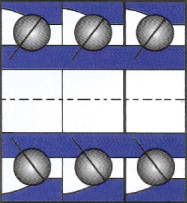

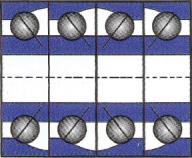

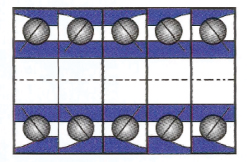

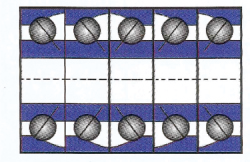

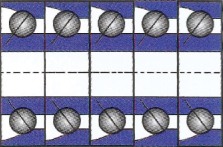

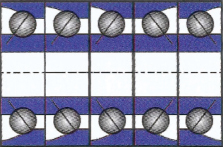

Angular Contact Ball Bearing Assembly Form

There are three types of bearing assemblies for two sets: DB type, DF type, and DT type. DB type is called “O” type, and DF type is called “X” type.

There are three types of bearing assemblies: TBT type, TFT type, and TT type.

The four types of bearing assemblies include QFC type, QBC type, QT type, QBT type, and QFT type.

The five types of bearing assemblies include PBC type, PFC type, and PT type PBT type, PFT type.

Bearing Applications

Deep groove ball bearings, as well as the advantages of simple structure, low-cost manufacturing, convenient maintenance, it is also suitable for high-speed running, no noise or low noise, high precision mechanical operation, it is one of the more commonly used bearings. It is used in various industrial fields such as household appliances, automobiles and industrial equipment.

Combine Harvester

Crane

Bulldozer

Loader

Graders

Automobile

Truck

Tractor

Dump Truck

Excavator

Technical Support & After-Sales Service

Technical Support

- Help With Your Choice: Don’t know which one to pick? Our technical guys can help you get the bearing you need based on the requirements you give us (load, speed, temperatures, etc.).

- How to Install: We provide you with excellent installation documents and video instructions on how to install your bearings.

- Troubleshooting: If you’ve got a problem like noise, vibration, or something overheating, I share with you what’s causing the issue and how to fix it like a pro.

- Support: Again, any kind of technical questions, you can reach out to us through Live Chat, email, or by phone and we’ll make sure that we get you the help quickly.

After-Sales Service

- Quality Warranty: Our products come with a 6-month quality warranty. If any of the product has quality problems unartificially, we will replace it for you. We will guarantee the quality of the products we sell to you for 6 months use.

- Return & Exchange Policy: If you receive a product with a quality issue, please contact our customer service within seven days, and we will arrange a return or exchange.

- Repair Services: We offer global repair support. Please send the item to us, and if it’s broken, we will process the repair and get it back to you as quickly as possible.

- Fast Response: MYWAY guarantees we will acknowledge your request within 24 hours of you making an after-sale service request. And we will do our best to have your issue resolved within 48 hours.

Selection of Angular Contact Ball Bearings

How to choose angular contact ball bearings

Which angular contact bearing do we select? The selection of the angular contact bearing will be determined by the operating condition and the available space for the bearing. Generally, the operating condition consists of the speed, the load conditions (how much axial and radial load) which angular contact bearings you should try to use, the lubrication method, etc. address the dominate issue first. If the main issue is speed, then you want a light series bearing with a fifteen-degree contact angle with a higher speed limit. If the main issue is taking high axial loads, then you want a heavy series bearing with a forty-degree contact angle. If you need a bearing to run at a high speed and take a heavy axial load, you want to use the bearings with the twenty-five-degree contact angle. And then you look at the space you have available to mount the bearing. Look in the catalog for the model and check the dynamic load, static load, and speed limit of the angular contact bearing you selected to verify the bearing meets your required speed and length of service life independent of the limiting factor.

Selection of Angular Contact Ball Bearing Precision

In China, there are bearing precision standards. There are different grades of these standards called P0, P6, P5, P4, and P2. P0 is the general grade, produced by a regular cost-effective manufacturing method suitable for mass production. Meaning this is good for you and your company’s budget! Precision gets better as you move from P0 to P2 and all grades relate to the dimensional and rotational precision. They mainly refer to dimensional accuracy and rotational accuracy (radial runout, axial runout, etc.). Dimensional accuracy is inner diameter, outer diameter, and width, which we’ve discussed. Rotational accuracy includes radial runout, axial runout, face-to-bore concentricity, and outer diameter perpendicularity.

Selection of Retaining Frame for Contact Ball Bearings

Types of Lubrication Methods for Angular Contact Ball Bearings and How to Choose

How to Choose Lubricating Grease for Angular Contact Ball Bearings and Control the Grease Filling Amount

Get Your Quote

What products do you want to see? Fill in the blanks below, and I will send you a price quote immediately.